There has been a lot of good work done recently as people consider the past and our relationship to it. Costumers are increasingly uncomfortable with uncontextualized depictions of historical dress and have had to come to terms with the truths of how the money that bought the pretty dresses was made. Obviously, dressing in trimmed silks and paste jewels is expensive, and in the North American colonies (and many other places) in the 18th and 19th centuries, the money that bought those goods was made on the backs of enslaved people.

Mary and Elizabeth Royall. Oil on Canvas by John Singleton Copley, about 1758. MFA Boston, Julia Knight Fox Fund, 25.49

But there’s an even harder truth waiting for us: even the ordinary clothes and everyday goods were often paid for with money made on the “free” labor of unfree men, women, and children. Not only did more people than we want to admit own other human beings, more people than we credit invested in slave trading voyages. And even if they didn’t directly invest in the voyages, they were often engaged in trade that intersected with the slave trade, or supported the plantations where captive people labored by indirectly feeding and clothing them.

The very hard truth is that it is even possible for tenant farmers in late-18th century Rhode Island to have supported and profited from slavery as the edible crops they grew were sold to feed those enslaved on rice, indigo, and cotton plantations in the south. Dairying– cheese making–was a means of making dairy protein stable and transportable, and vegetables like onions expanded diets.

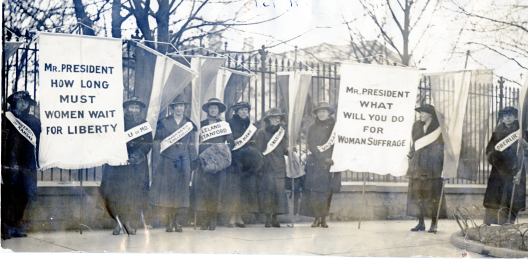

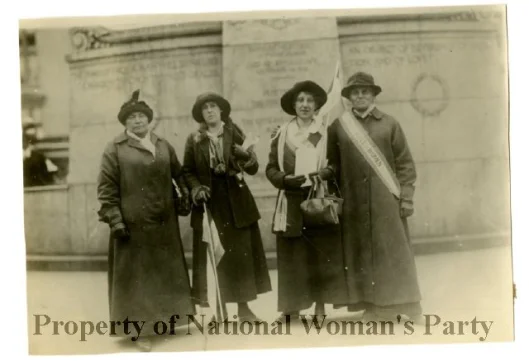

Chattel slavery made the world we inhabit–both now and when we put on the clothes of the past–no matter what class level we represent. Some would argue that we should no longer put on those clothes. I sit in a place of privilege as a white woman and one who has never engaged in Civil War living history or costuming, a period that is particularly fraught. But even interpreting a 1910s suffragist means you must confront the demons that are not past: racism, Jim Crow, voter suppression, and the truths of how the leaders of the women’s suffrage movement treated Black women. We are always complicit.

Elizabeth Freeman (“Mumbet”). Miniature portrait, watercolor on ivory by Susan Anne Livingston Ridley Sedgwick, 1811. Massachusetts Historical Society Artwork 03.147

But I think that means we can, and even should, continue to interpret the past through all the clothes. Telling all the stories more fully helps us move forward. All of us must own the truths of how we reached this place in American history. All of us must own who we might or might not have been. We share a history and a culture, even when many are excluded. That exclusion is part of the story. For a time it needs to be the main story, as we as a nation, as interpreters of the past, see the world anew, listen to voices that have gone unheard.

It will be a long time before any of us are able to resume the work we did before, interacting directly with the public, but that gives us a chance to rethink what we do, and how we do it. For some, abandoning the costumes of a problematic past may be the answer. For others, considering more fully the characters we represent may offer a way to carry on.

Alice, d. 1802. Engraved from an original sent from America, by Mackenzie, [London] : Pub. Jan. 1. 1803, by T. Hurst, Paternoster-Row. (1804?) The Library Company of Philadelphia

I have thought a fair bit about the 2019 Occupied Philadelphia event. Once again, I portrayed Elizabeth Weed, the widowed pharmacist with a sickly son who went on to marry Thomas Nevell, architect and builder. Elizabeth owned a business and a house, but did she own people? A visitor to that event asked me, “Did you own slaves?” and I had to think about it. It wasn’t a question I had asked myself before, and that’s a clear failure since I had done research on the nature of labor in mid-18th century Philadelphia as indentures gave way to enslavement. I don’t think Elizabeth Weed owned anyone; I can find no evidence, but I need to look again, and more deeply.

Rebecca Flower Young, though, is another story. By the time she lived in Baltimore with her daughter, who made the Star-Spangled Banner now at the Smithsonian, her daughter had a 13 year old African American or African indentured servant. The young woman’s name is lost to time, but the fact of her existence and the trajectory of Young’s life make me wonder about her time in Philadelphia. As an Army contractor, she had women sewing for her, and she probably sewed herself. The labor of the indentured servant girl in Baltimore allowed Mary Pickersgill to concentrate on working for money. While the Smithsonian may describe the indentured girl as “helping Pickersgill make the flag,” chances are that her housework– tending fires, cooking meals, cleaning the house, permitted Pickersgill, her nieces, and her mother to do the sewing and cutting. Similar work was necessary to support Rebecca Young’s enterprise in 1780s Philadelphia. Who performed it? Were they paid, or unpaid?

If (when) I can once again put on the stays, petticoats, and gowns that allow me to interpret Rebecca and Elizabeth, my work must include a discussion of the labor that supported their work, and who performed that labor. I will have to challenge the public to imagine a more complete history of the United States, one that is both starker and more nuanced. The country was built and flourished on the labor of unwilling captives, which we have concealed behind myths about the founding heroes and heroines. Only when we admit those truths can we truly begin to portray the past, inhabit those clothes, and engage with the public.

About the Images:

This overmantle painting shows a wealthy Rhode Island planter family with their African slave, a rare depiction of the realities of New England life. John Potter was a wealthy South Kingstown, Rhode Island planter, notorious for his counterfeiting activities of 1742. Many of the people enslaved in Rhode Island were forced to work on the large farms in what is now Washington County.

Mary and Elizabeth Royall were daughters of Isaac Royall, who owned the largest number of enslaved people in Massachusetts. The Royall House and Slave Quarters in Medford, MA (just north of Boston), interprets the lives of the family and those they enslaved.

John Brown‘s dinner set of Chinese export porcelain in emblematic of his wealth, which was derived from many sources, including the slave trade. The China Trade decorated his brick mansion house in Providence, but war profiteering, distilling, and the slave trade built it. He was an unapologetic– indeed, an enthusiastic– defender of the slave trade as a source of revenue for the New Republic.

Elizabeth Freeman (“Mumbet”), born into enslavement in 1742, was the first enslaved African American to file and win a freedom suit in Massachusetts. The Massachusetts Supreme Judicial Court ruling, in Freeman’s favor, found slavery to be inconsistent with the 1780 Massachusetts State Constitution.

Alice, known variously as Black Alice and Alice of Dunk’s Ferry, was a native of Philadelphia and a slave, born to parents who had come from Barbados. She is said to have been 116 at the time of her death in 1802. In extreme old age Alice received many visitors who enjoyed hearing stories about early Philadelphia and its famous first settlers, including William Penn and Thomas Logan. Alice was also a lifelong worshiper at Christ Church in Philadelphia. “Being a sensible intelligent woman, and having a good memory, which she retained to the last, she would often make judicious remarks on the population and improvements of the city and country; hence her conversation became peculiarly interesting, especially to the immediate descendents of the first settlers, of whose ancestors she often related acceptable anecdotes.” from Thomas, Isaiah. Eccentric biography; or, Memoirs of remarkable female characters, ancient and modern (Worcester, 1804), plate preceding p. vii. and p 9.

Further Reading:

Many of these are available in paperback; check in the university press sites as many are offering discounts right now that make them competitive with Amazon, while supporting them directly. Inter-library Loan is also an excellent and often free option; check with your local library.

Anderson, Jennifer L. Mahogany: The Costs of Luxury in Early America. Boston: Harvard University Press, 2012.

Dunbar, Erica Armstrong. Never Caught:The Washingtons’ Relentless Pursuit of Their Runaway Slave, Ona Judge. New York: Simn and Schuster, 2017.

Clark-Pujara, Christy Mikel. Slavery, emancipation and Black freedom in Rhode Island, 1652-1842. Ph.D. Thesis, University of Iowa, 2009

Clark-Pujara, Christy. Dark Work: The Business of Slavery in Rhode Island. New York: NYU Press, 2016

Gagnon, Jeffrey Charles. (Re)creating Social Life Out of Social Death : cross-cultural alliances in the circum- Atlantic, 1760-1815. Ph.D. Thesis, University of California San Diego, 2012.

Gigantino, James G. II. The Ragged Road to Abolition: Slavery and Freedom in New Jersey, 1775-1865. Philadelphia: University of Pennsylvania Press, 2016.

Hartigan-O’Connor, Eleanor. The Ties That Buy: Women and Commerce in Revolutionary America. Philadelphia: University of Pennsylvania Press, 2011.

Lin, Rachel Chernos. “The Rhode Island Slave-Traders: Butchers, Bakers, and Candlestick-Makers.” Slavery and Abolition 23:3, 21-38. (2002)

Rapplye, Charles. Sons of Providence: The Brown Brothers, the Slave Trade, and the American Revolution. New York: Simon and Schuster, 2006.

Salinger, Sharon V. “Artisans, Journeymen, and the Transformation of Labor in Late Eighteenth-Century Philadelphia.” The William and Mary Quarterly, Vol. 40, No. 1, 62-84. (January 1983)

Smith, Billy G. “Poverty and Economic Marginality in Eighteenth-Century America.” Proceedings of the American Philosophical Society, Vol. 132, No. 1, 85-118 (March 1988)

Smith, Billy G. “The Family Lives of Laboring Philadelphians during the Late Eighteenth Century.” Proceedings of the American Philosophical Society, Vol. 133, No. 2, Symposium on the Demographic History of the Philadelphia Region, 1600-1860, 328-332 (June 1989)